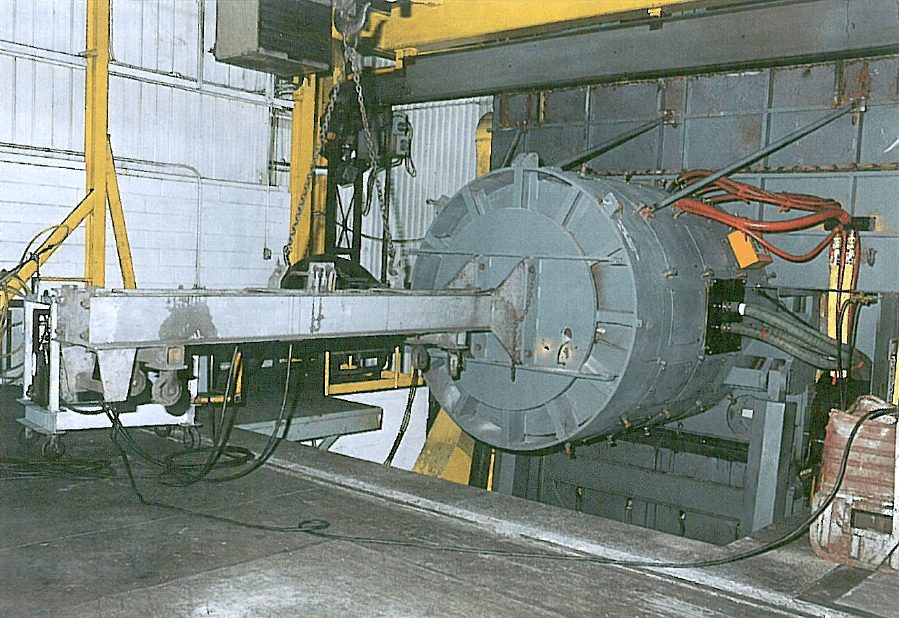

Push-Out Lining System

Decrease lining turnaround time and improve work environment.

Functionality

Rim blocks and a pusher block are fitted into the bottom of your furnace. Once the furnace lining is spent and the furnace has been emptied and allowed to cool, the refractory crown and spout are broken off manually to facilitate free movement of the lining. The furnace is then fitted to a horizontal position. A hydraulic pusher mechanism is mounted to a bottom weldment on the furnace and the hydraulically driven pusher plate ejects the lining into a hopper.

Enhance Your Work Environment

EMSCO’s Push-Out Lining System is operated by remote control, reducing employee exposure to any noise and dust generated by the system. Flush mounting receptacles can also be added to further improve the environmental conditions.

Furnaces from any manufacturer can be retrofitted with a Push-Out Lining System. Contact EMSCO today and discover how Push-Out Lining Systems reduce the risk of employee accidents and coil damage while transforming your foundry into a safer and more productive operation.