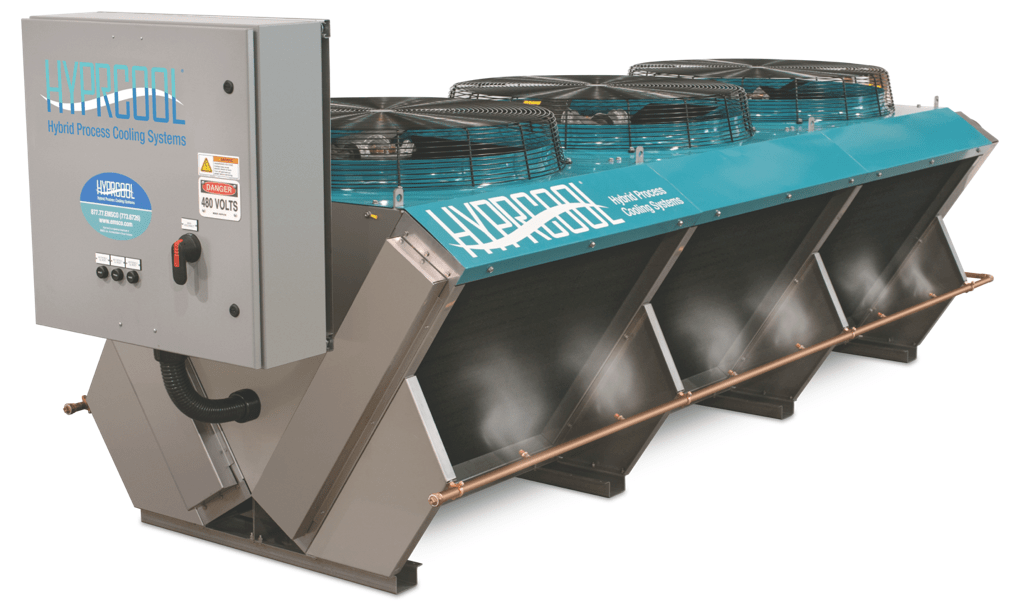

HyprCool® Hybrid Process Cooling Systems

Advance your process cooling system.

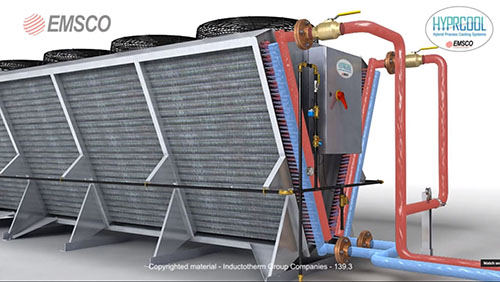

HyprCool® Hybrid Process Cooling Systems by EMSCO cross the divide between traditional dry air and fluid cooling systems by applying hybrid adiabatic technology. This science eliminates problems with overheating during the summer (dry air coolers) or freezing during the winter (fluid coolers). The hybrid adiabatic technology applied to HyprCool systems yields significant energy, water, health, and space savings – resulting in decreased cost and increased efficiency. HyprCool Hybrid Process Cooling Systems are custom manufactured in Alabama, USA to cool a variety of industrial processes.

The latest addition to the HyprCool product line features a 90″ coil height, and delivers up to two times the heat rejection previously available from HyprCool systems by utilizing a larger cooling surface and enhanced spray system.

HyprCool increases efficiency in these key areas:

Energy

Energy

HyprCool fans turn on in stages and only run when required to maintain the desired operating fluid temperature. NEMA Premium Efficiency Motors are used in compliance with the Energy Independence and Security Act of 2007.

Water

Water

The HyprCool hybrid adiabatic system uses a fine spray of water only during the hottest months of the year when process fluid and ambient air temperatures dictate. As a result, HyprCool systems consume as little as five percent of the water a traditional evaporative cooling tower would.

Health

Health

HyprCool eliminates the standing water found in evaporative cooling towers – thus eliminating one of the primary breeding grounds for Legionella pneumophila – the bacteria that causes Legionnaires’ disease.

Space

Space

Square footage is a premium in most foundries and industrial facilities. HyprCool features a significantly smaller footprint than traditional dry coolers.

EMSCO HyprCool Hybrid Process Cooling Systems are used in a number of industries, including:

- Foundries/Melting

- Heating/Forging

- Plastic/Rubber Molding

Call 877.77.EMSCO to find the best cooling solution for your operational requirements or to learn more about our foundry services.

Features

- Copper Tubing for excellent thermal conductivity and corrosion resistance, critical in de-ionized water applications.

- Stainless Steel Construction protects HyprCool systems from corrosion and ensures your system will be operational for years.

- Poly-Coating engineered to resist mineral deposits and maintain optimum cooling capacity.

- Misting Nozzles apply a fine spray of fresh water to the air entering the unit during the hottest months of the year, increasing the HyprCool’s cooling capacity when dictated by the ambient air temperature.

- Fans on the HyprCool cycle on and off in stages to maintain the exiting water temperature at a pre-determined set point, reducing energy consumption. EC or NEMA fans available.

- Space is at a premium in most facilities, and the HyprCool features a significantly smaller footprint than traditional dry coolers.

- Control Panel is factory-installed on the unit and is fully contained, requiring only the primary power connection to be made on-site. PLC or digital controls available. All EMSCO panels are UL/UL-C 508A Industrial Controls.

- Lift Points are bolted to the internal structure of every fan section for quick, simple, and safe lifting and positioning.