Water-Cooled Power Leads

Optimum Contact and Conductivity

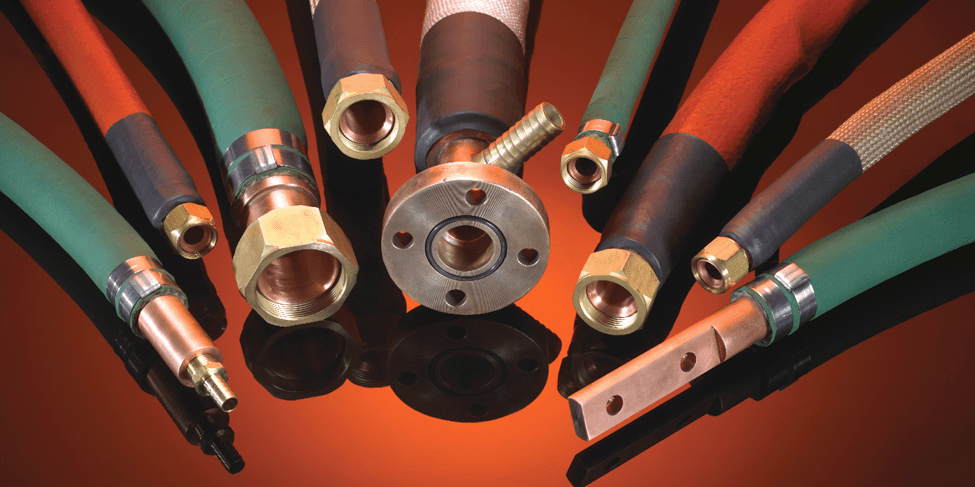

EMSCO’s induction melting furnace Water-Cooled Power Leads are assembled with precision using premium materials to ensure maximum flow.

High Performance

High performance demands that a water-cooled lead have good electrical efficiency and a rugged, durable hose. EMSCO power leads are copper rated at 101% electrical conductivity by the IACS and soldered to the terminal to ensure optimum contact and conductivity.

This cable is covered with a non-conductive hose constructed of a nitrile tube, multi-ply reinforced center and a neoprene cover, with a 1000-psi minimum burst pressure and a continuous operating pressure of 250 psi.

Flange-type terminals are resurfaced and silver-plated for optimum contact and electrical conductivity.

High Flow

A custom designed, high tonnage press used in conjunction with special hardened custom dies that produce openings to provide consistent, maximum water flow through every terminal manufactured. The heavy gauge, strong yet flexible, copper cable resists breaking and bird-nesting that can restrict flow. Also, the multi-ply reinforcement of the hose is flexible, but resists collapsing or kinking. The cable is helixed around a spiral center to maintain maximum and consistent water flow for flange-type cables and the newer designs incorporating internal core springs or hoses.

Low Maintenance

For terminals requiring a standard 37° flare, EMSCO uses a hydraulically powered production tool. This power flarer produces a precise and consistent flare on each terminal to assure a watertight connection. Each hose is secured with pneumatically applied stainless steel clamps, utilizing the most technologically advanced tooling available on the market. This equipment assures consistent clamping pressure at each application. This results in leak-proof joints.

The rugged construction of the hose provides excellent resistance to abrasion and will not be damaged if continuously subjected to 200°F temperatures. The combination of high-performance, high-quality materials and state-of-the-art equipment results in an efficient, low maintenance, and long-lasting product.